EET Hydrogen Power, billed as Europe’s first hydrogen-ready combined heat and power plant, is under development in the UK, with FID imminent. To be located at the Stanlow refinery, it would be part of the HyNet cluster. By Rob Wallace, CEO of EET Hydrogen Power

The global shift towards clean energy solutions has placed hydrogen as a significant pillar in the next great energy transition. With rising pressures to decarbonise and achieve net-zero targets, we believe hydrogen power plants are a critical path for heavy industries and power generation. Essar Energy Transition (EET), with our ambitious EET Hydrogen Power business, is poised to lead this charge. At the heart of this effort lies the decarbonisation of the Stanlow Refinery and the wider HyNet cluster in North West England, as we make strides towards a hydrogen-fuelled future. HyNet received a welcome boost in October with an announcement by the UK government confirming its support of the cluster.

Role of EET in the transition

Essar Energy Transition is at the forefront of the UK’s decarbonisation goals, investing in a sustainable energy transition to create the country’s premier low-carbon energy hub. EET’s portfolio includes EET Fuels’ Stanlow Refinery, which is on track to become the UK’s first low-carbon refinery, EET Hydrogen, which is developing over 1.35 GW of blue and green hydrogen production capacity, and EET Hydrogen Power, Europe’s first large-scale hydrogen-ready combined heat and power (CHP) plant.

EET Hydrogen Power, currently under development, aims to deliver a CHP plant at the Stanlow refinery, with commissioning for phase one expected by 2027. This project is a vital piece of the broader decarbonisation efforts of the HyNet cluster, which will leverage hydrogen, carbon capture, and the creation of a highly decarbonised industrial hub.

Visualisation of hydrogen ready CHP units that will comprise EET Hydrogen Power (Image: EET Hydrogen Power)

The project is a testament to EET’s commitment to reducing carbon emissions by up to 95% by 2030.

Decarbonising Stanlow and the HyNet cluster

Driving the decarbonisation of the Stanlow refinery is one of the key goals of EET Hydrogen Power. Stanlow is the UK’s second largest oil refinery, and its transformation into a low-carbon facility is integral to the region’s overall industrial decarbonisation strategy. By implementing hydrogen as a primary fuel source, EET Hydrogen Power has the potential to lead decarbonisation of power generation in the region.

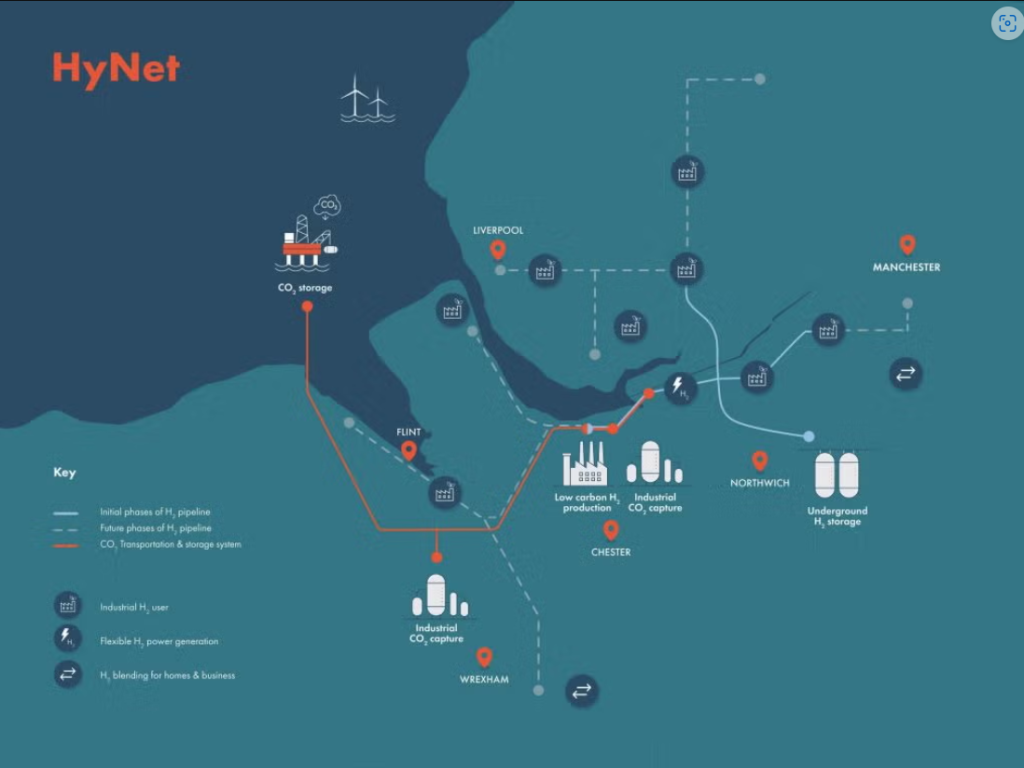

Stanlow itself is strategically positioned within the HyNet cluster. HyNet aims to make the North West of England a leading industrial decarbonisation hub by developing low-carbon hydrogen production and infrastructure, coupled with carbon capture and storage (CCS).

Schematic of the HyNet cluster (Image: HyNet)

By working within the HyNet cluster, EET Hydrogen Power can tap into this robust network, supporting regional industrial users with low-carbon energy solutions and further driving the UK’s net-zero ambitions. In addition to decarbonising Stanlow, the project will serve other industrial users in the area, further cementing its importance in the HyNet cluster.

The technology

The core technology behind EET Hydrogen Power is a gas turbine based CHP system optimised for hydrogen combustion. This system will provide electricity and steam to the Stanlow refinery and local industrial users.

Phase one of the project will deploy 49.5 MW of electrical generation capacity and up to 6000 tonnes/day of steam production capacity. The capacity will eventually increase as the project expands towards 250 MW.

Initially, the CHP system will operate using refinery off-gas as its primary fuel, but by 2028, hydrogen will be sourced from EET Hydrogen’s HPP1 plant. This setup ensures that EET Hydrogen Power will run on low-carbon hydrogen, ensuring the entire ecosystem operates sustainably.

The deployment of hydrogen-ready gas turbines marks a significant technological shift in power generation. These turbines offer fuel flexibility, being capable of running on both hydrogen and natural gas, which allows smoother integration into existing systems while maintaining readiness for a future where low carbon hydrogen fuels are available. We are currently in the final stages of selecting the most cost-effective and efficient turbine supplier.

Getting to 100% hydrogen readiness: challenges and solutions

The transition to 100% hydrogen readiness presents significant technical and logistical challenges. One of the major hurdles is the development of infrastructure that can handle hydrogen as a primary fuel source. Hydrogen has different combustion properties compared to natural gas, requiring specialised turbines, pipelines, and storage solutions. The high diffusivity and flammability of hydrogen also necessitate stringent safety measures.

Moreover, the economic feasibility of hydrogen-based power generation is closely tied to hydrogen production costs and the regulatory framework supporting its use. Currently, hydrogen remains more expensive than natural gas, though government support, such as the UK’s price linkage between hydrogen and natural gas, help mitigate this cost. Scaling up hydrogen production, particularly blue and green hydrogen, will be essential to making it a cost-competitive energy source.

We are acutely attuned to the need for stakeholder buy-in to the plans. Hydrogen power remains a relatively new technology, and both industrial users and the public need reassurance about its safety, reliability, and cost-effectiveness. We are tackling this through comprehensive planning, risk assessments, and transparent partnerships with key stakeholders, ensuring a smooth transition to hydrogen power.

Implementation: next steps

The implementation of EET Hydrogen Power will be carried out in phases, with phase one scheduled for completion by 2027. The front-end engineering design (FEED) study for phase one was initiated in December 2023, and final investment decisions are expected by the end of this year. Construction will begin in 2025, with the CHP system initially running on refinery off-gas until the hydrogen supply from HPP1 is ready in 2028.

Final investment decision is crucial in ensuring the project moves forward on schedule. The FEED study, conducted by TATA Consultancy, is evaluating the best options for gas turbine procurement, fuel flexibility, and long-term operational sustainability.

As EET Hydrogen Power progresses, collaboration with key partners, including turbine suppliers and local industries, will be critical to ensuring the success of the project. Procurement of turbines, heat recovery steam generators, and other critical equipment will need to align with the project’s timeline. Moreover, securing energy service agreements (ESAs) with industrial users will ensure the long-term commercial viability of the project.

Looking ahead, EET Hydrogen Power is poised to decarbonise and modernise power generation at the Stanlow refinery but also to serve as a blueprint for similar projects globally. The successful execution of this project will demonstrate how hydrogen power can drive industrial decarbonisation, support regional economic growth, and contribute to the global effort to combat climate change.

Pioneering a hydrogen-powered future

EET Hydrogen Power is not just an energy project; it’s a bold statement about the future of energy and the path to decarbonisation. By leveraging cutting-edge technology, government support, and strategic partnerships, EET Hydrogen Power is leading the way in creating a low-carbon energy hub in the UK.

As hydrogen power continues to evolve, it holds the promise of transforming power generation and offering a clean, sustainable alternative to fossil fuels. Through innovative solutions, collaborative efforts, and meticulous planning, EET Hydrogen Power is set to change industrial energy use in the UK and beyond.

Source: Modern Power Systems